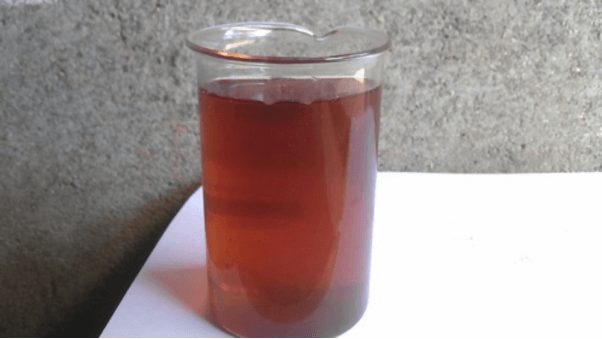

TPEG HPEG LPEG refers to a material fondly used in the manufacture of polycarboxylate superplasticizer. The formed component is identified as a high ranger water reducer. It is also an additive used in creating high strength concrete such as plasticizers, which are the primary chemical compounds enabling the production and creation of concrete with carbon. The said additives are often utilized in slump retention performance. Some of the end products of these processes are such as gushing concrete, polycarboxylate, in addition to hydro concrete. These products are commonly used in spearheading different engineering projects. Here are additional amazing facts about TPEG materials.

- Operating Mechanism Of TPEG HPEG LPEG Materials

Usually, TPEG HPEG LPEG materials are used in the manufacture of plasticizers, which are also known as lignosulphonates. This is sodium salt, coupled with a synthetic polymer. The compounds therein are used as superplasticizers to manufacture crosslinked polymers. These polymers are then used in creating surfactant properties. In the long run, they will also be utilized in the manufacture of gravel and fine sands.

- Manufacturing Concrete And Cement Additives

TPEG HPEG LPEG is used in the manufacture of concrete as well as cement additives. It contains a chemical compound that enhances the durability of walls during and after construction. Some of these minerals include elements that a unique molecular structure coupled with a branch structural design. The design is usually applied in the creation of fresh concrete in the manufacturing processes of cement. By adjusting the primary branch structure, the main hydrolysis rate can easily be adjusted to fit into the time of the protective effect.

- The Technical Performance Of TPEG HPEG LPEG Materials

TPEG materials have a high rate of water reduction coupled with the ability to produce a large fluid concrete. This is usually under significantly low temperatures. The material also has a low water-cement ratio that quickly shortens the steaming cycle while accelerating the module turnover. When in use, most professionals have admitted that the setting is quite fast, and the surface time of that component is fabricated as well. Therefore, being a durable material, TPEG is known for its strong yet robust nature. Even in high temperatures, these elements are not interfered with by any means.

- Workability Is A Vital Element To Consider In The TPEG HPEG LPEG Materials

The workability of TPEG HPEG LPEG materials is easily affected by its composition. In the construction industry, the workability of concrete materials, including water content, sand aggregate properties, like size, shape, grading, and mix design ratios, applied in the utilization of admixtures. Therefore, every process therein and the material involved in the mixing process affects the workability of TPEG HPEG LPEG materials.

- TPEG HPEG LPEG Materials Have Relatively Low Shrinkage

Being a new yet complex raw material, TPEG HPEG LPEG is prominent for having a relatively lower shrinkage rate when it comes to cracking. This feature makes it a viable element in the construction industry.

Take-Home

TPEG HPEG LPEG materials are a vital element in the construction of concrete. As you may know, concrete is an essential construction in the building industry. Therefore, more professionals rely on the ability of TPEG HPEG LPEG materials to produce durable products in the long run.