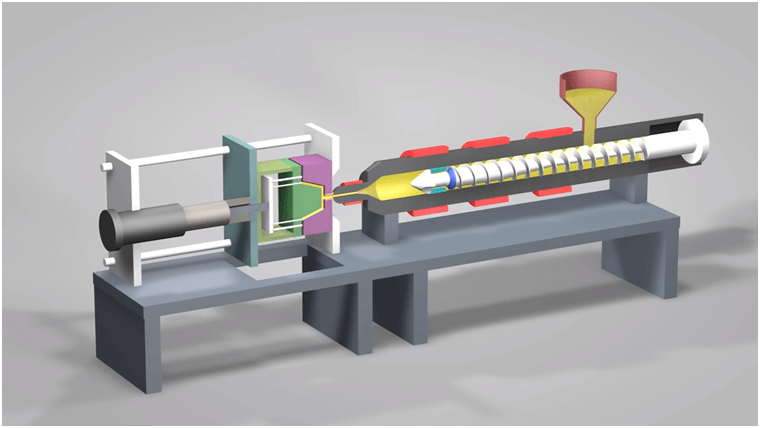

Unquestionably, plastic injection molding is a significant plastic part producing method. The technique can be adapted for various functions, due to its multiple benefits in different fields. Arguably, the process in question is the most efficient and common form of molding used globally due to its simplicity and reliability, among other advantages. In this article, several injection molding advantages that make it extremely versatile will be discussed.

- Enhances high efficiency

Comparatively, the molding method in the discussion is extremely fast than other molding techniques. The process can generate plastic parts in mass form from one mold at a relatively high speed. Consequently, the injection molding cost is significantly reduced, hence making the activity relatively cheap and efficient.

- Strength enhancement

Indisputable, product strength is one of the primary factors that you need to consider while purchasing any plastic material. Such products are highly durable, thus can be used for a more extended period. As a result, the plastic injection molding companies have maximized on the process in question because it allows them to apply fillers. Fillers application in the molds helps in reducing the density of the plastic as they add greater strength to the part that is being molded.

- Reduced raw material wastage

Injection molding materials are relatively expensive; thus, they should be well utilized. However, injection molding of the plastics allows you to recycle the plastics, thus making the product and the final product relatively cheap. Besides, the techniques minimize material wastage in the manufacturing process.

- Color and material flexibility

There is a wide selection of polymers materials that you can use in plastic products manufacturing. The injection molding machine is capable of handling various materials in plastic products manufacturing, hence creating a variety of items that the clients. Some of the significant variables that you can consider while choosing the right product for your project are such as tensile strength, impact strength, and heat deflection capability, among others.

- Enables complex designs

In the injection molding steps, the injection molds are exposed to high pressures, thus pressing the molds in use tighter than other similar processes. Consequently, the final product becomes stronger and durable. However, the use of computers in the manufacturing and designing process assists the manufacturer to create various and more flexible designs, hence giving the clients a variety of choices.

- Can use multiple types of plastics simultaneously

In the injection molding process, several plastic models can be simultaneously used to manufacture a product. Subsequently, this co-injection process helps in producing stronger products and reduces production cost. Also, the energy usage is significantly reduced due to a lesser melting point of the secondary plastic.

The bottom line

Indeed, plastic parts are widely used in the modern world. However, you require a manufacturing technique that is favorable to both the manufacturer and the client. Consequently, there are various injection molding advantages associated with plastic injection molding. Some of the benefits in question are such as co-injection ability, attainment of intricate designs, material and color flexibility, lesser material wastage, strength, and material enhancement.