Centrifugal pump and boilers are some of the machines that are under the risk of overheating and cavitation. When the two are not taken care of, they might lead to total damage to the concerned machines permanently. However, automatic recirculation valve works to control overheating and cavitation even in centrifugal pumps. To achieve this, it controls the flow of liquid into the centrifugal pump. This article will highlight the major automatic recirculation valve specifications you need to know.

- Design

Automatic recirculation valves are designed in a standard model. However, if you need your valve to be customized to meet your specific needs, ask your manufacturer for the option available for you. Suppose your centrifugal, crude oil pump or boiler is used in harsh conditions; a standard valve will strain to work efficiently and protect your machine. It is therefore essential to consider the environment in which you are from so that your manufacturer to design a valve that fits it.

- Functions Of The Valve

Automatic recirculation valve manufacturers have designed them to perform in different tasks. Here are some of the tasks where an automatic valve can work effectively,

- Bypass flow

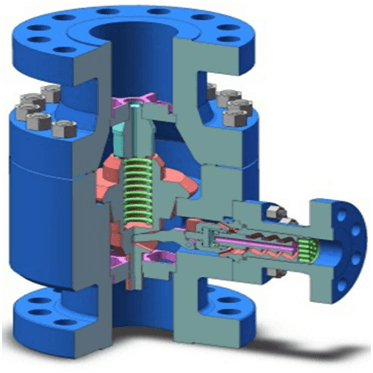

The bypass valve senses the flow of the liquid from the pump and controls the flow. The presence of the bypass valve ensures that you will not need to use electric power or air support to control the liquid flow.

- Check valve

The check valve is placed below the outlet but above the inlet from the pump, and it acts as a barrier against reverse flow.

- Pressure control

Automatic recirculation valve pressure drop is in the bypass segment of the recirculation valve. It functions is to drop pressure that could affect the inflow side of the pump.

- Operation Of The Valve

One of the automatic recirculation valve specifications is how it operates. First thing you should remember, the valve is automatic and it opens when it detects there is enough liquid in the pump to be let out. However, when the fluid decreases, the side outlet closes, and the bypass valve control allows the liquid to flow back to the pump, preventing the risk of cavitation and overheating.

- Installation

Nonetheless, for the automatic recirculation control valve to function efficiently, you must know how to install it. But, unless you possess the knowledge, avoid installing it on your own. Hire an expert to lay the valve on the outlet of the pump.

So, before installing the arc valve, ensure the lines are clean and that there is no pressure in the pipes. By the aid of an expert, you can rule whether the valve is right for your pump or not.

It is essential to know, the valve has a unique number, and in case one of the parts spoils, use the unique number to purchase the replacement. However, during the routine maintenance of your pump, consider checking the valve to and ensure it is rusty as this may hinder the correct flow of the liquid.

Take Away

For your pump to work efficiently, you must consider the automatic recirculation valve specifications before buying. It is therefore essential to use the knowledge of an expert to decide on the best valve for your pump.