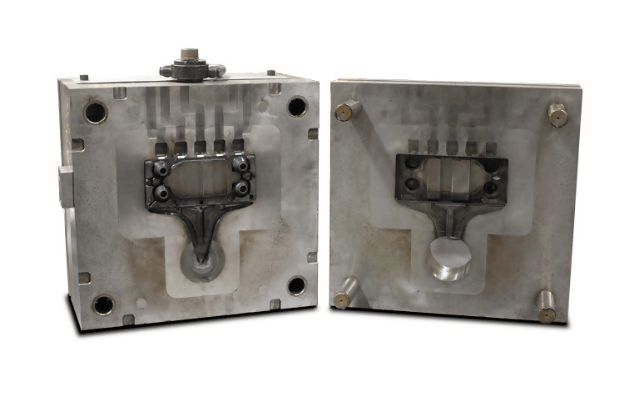

Mold design is a crucial step in die casting. Molds are the parts in die casting where molten metal is forced under extremely high-pressure during die casting. The design of the mold directly affects the shape, dimensions, configurations, quality, and general uniformity, among other physical and structural aspects of the final product. Mistakes made in the mold design can result in corrosion of the material, production of low-quality products, or ineffective designs, among other challenges. Other implications include effects on production time and consumer satisfaction. It is, therefore, essential to make sure that the quality of the casting mold design is outstanding.

Ways in which mold can be designed

- Modification of tooling

- Conversion of the existing molds into PDC machines at a low cost

- Reverse engineering the existing molds

- Insert tooling

- Complete mold making or mold design

Different projects may require different mold designs according to the specification of the task. When coming up with mold design, there are some factors you have to consider;

The degree to which the mold can be tampered with

This is referred to as the die draft. For you to eject the casting from the die smoothly, you need to make sure that the die draft is precise. However, the draft is not constant; it varies depending on the wall-angle and other features of the die casting machine and the process, including the alloy type used, the shape of the wall, penetration of the mold, and how it can affect the process. The dimensions of the mold can also change the die draft.

Fillets

The fillet is a concave junction employed in smoothing the intended end product angles surface. Sharp mold corners can object to the process of casting. Therefore, in die casting, mold designs with rounded edges are the most common as they reduce the chances of errors arising.

Parting surface

This is the part that connects the different sections of the mold. An imprecise parting surface would result in deformation of the end product and seeping of the molten between the gaps in frame pieces.

Cooling system

Since the molten metal that is passed through the mold feature extremely high temperatures, the mold design should feature a cooling system to maintain the quality of the parts and the cycle time.

Specifics of the project

Such specifics include symbols such as logos. When creating a mold design, it is crucial to consider such details as they may require little or less raw materials hence increasing or reducing the amount of work.

Holes and windows

These features affect the ease with which the completed molding can be ejected hence enabling the creation of subsequent drafts.

Knobs and Ribs

Die-cast knobs serve as points of mounting in mold design, and ribs are used to increase the strength of the materials that are lacking in thickness.

Conclusion

Some die casting firms run their mold design processes while others hire professionals for the task. But for you to come up with the best mold design, it is vital to research the topic adequately to ensure high-quality results.