Filing equipment used in offices and other places come in different forms. Traditionally, the term filing equipment was used to refer to office furniture as important data was stored mostly in drawers and cabinets. However, file storage systems in the office and at home went through a series of changes when computer storage was introduced. Not too long after the thriving of this type of storage system was cloud storage introduced. Currently, the latest data storage trend is NAS.

A Raspberry Pi NAS is a network that is connected to a computer. The role of NAS is to provide a file-based storage system that different devices can access through a network. A Raspberry Pi NAS Unit is, therefore, a type of server that does not have a keyboard or a display. However, the unit is controlled over a network on which it is configured using a browser. In this post, we look at DAS and NAS, their differences and similarities.

The Difference Between NAS and DAS

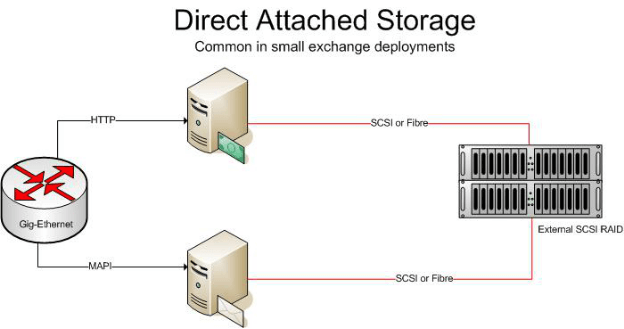

NAS is a Network-attached Storage while DAS is a Direct-attached Storage. Below are a few of the major differences between these two storage systems;

- The main difference between DAS and NAS is the fact that DAS is normally an extension of a server that is already in existence. This means that it does not require a network of its own. On the other hand, NAS is a sort of server through which files are saved and shared over a network.

- In terms of performance, NAS beats DAS because it can be precisely tuned for file serving. This is a feature that is not available in DAS.

- Another difference is that DAS unit is limited to a specific host. However, using NAS, it can be used by other hosts. Some techies explain that DAS is the building block of NAS.

- DAS is also connected to a server or a particular work station directly. On the other hand, NAS requires an intermediary. The intermediary is normally either a network or a USB cable with which the unit can be connected to a computer.

- One of the main cons of DAS is the fact that it does not provide efficiency for sharing data with other servers. On the other hand, NAS allows low volume access to incredible amounts of storage by more than one user.

- The performance of NAS is greatly dependent on the speed and congestion of the network. On the other hand, the performance of DAS is dependent on the speed and congestion of its connected server.

- Finally, DAS is more customizable than NAS in terms of its hardware and software because it is a general-purpose server.

Similarities between DAS and NAS

Below are some similarities between these two storage systems;

- Both NAS and DAS are used to increase the availability and accessibility of data. They also both work by using either RAID or clustering technology.

- Another similarity is the fact that they both can have different amounts of cache memory. The amount of memory on each affects its performance.

Conclusion

Choosing the best data storage mechanism can be hectic. However, you can lessen the workload by simply looking at the pros and cons of each mechanism.